PVC Roofing Sheet Manufacturers in Pune

if you Are Looking For PVC Roofing Sheet Manufacturers in Pune So Stop Searching Durga Industries is here To Help You We have Qualified And Experience Expert And Main Thing Can not Compromise The Product Quality And Clients Satisfaction Manufacturing PVC (Polyvinyl Chloride) roofing sheets involves a series of processes that transform raw PVC materials into durable roofing materials. PVC roofing sheets are popular due to their lightweight, durability, and resistance to various weather conditions.

Raw Material Preparation:

PVC Resin: The primary raw material for PVC roofing sheets is PVC resin, which is derived from petroleum or natural gas.

Plasticizers: Plasticizers are added to the PVC resin to make it more flexible and workable.

Stabilizers: Stabilizers are used to prevent the PVC from degrading when exposed to heat and UV radiation.

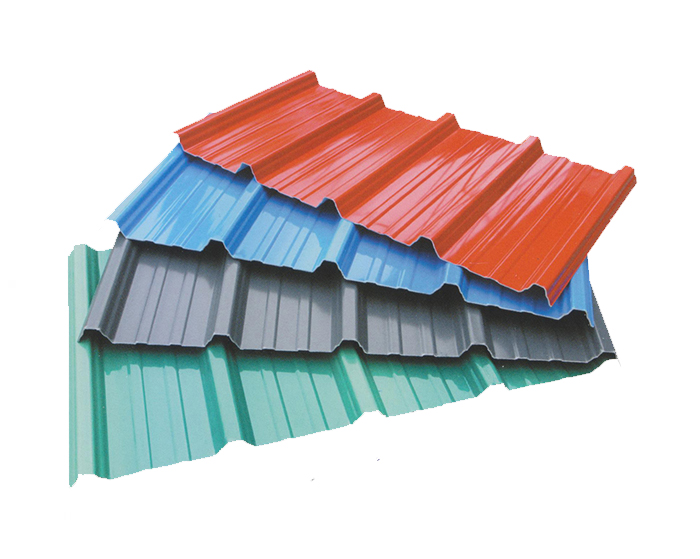

Pigments: Pigments are added to provide color to the roofing sheets.

Other additives: Various additives such as fire retardants and anti-UV agents may be incorporated to enhance the performance of the roofing sheets.

Mixing:

The raw materials are mixed together in a high-speed mixer to create a homogeneous compound.

Extrusion:

The mixed compound is fed into an extrusion machine, where it is heated and forced through a die to form continuous sheets of the desired thickness and width.

The extruded sheets are then rapidly cooled to solidify them.

Embossing and Texturing (Optional):

Some PVC roofing sheets may undergo embossing or texturing to enhance their aesthetics and provide better grip.

Cutting and Sizing:

The continuous PVC sheets are cut to the desired length and width using cutting machines.

Quality Control:

Quality control procedures are carried out to ensure that the roofing sheets meet industry standards in terms of thickness, color consistency, strength, and other relevant properties.

Printing (Optional):

If branding or additional information is required on the roofing sheets, printing can be done at this stage.

Packaging:

The finished PVC roofing sheets are packaged and prepared for distribution and sale. Packaging can include protective layers to prevent scratching and damage during transportation.

Distribution:

The roofing sheets are distributed to retailers, construction companies, or directly to consumers.

Installation:

PVC roofing sheets are installed on roofs using appropriate fasteners and installation techniques.

Maintenance:

PVC roofing sheets require minimal maintenance but may benefit from periodic cleaning and inspection.

It's important to note that specific manufacturing processes may vary depending on the manufacturer and the type of PVC roofing sheets being produced. Additionally, safety precautions and environmental considerations are crucial throughout the manufacturing process, especially when dealing with PVC, which can release harmful gases if not processed correctly. Manufacturers must adhere to local regulations and best practices to ensure both product quality and environmental responsibility.