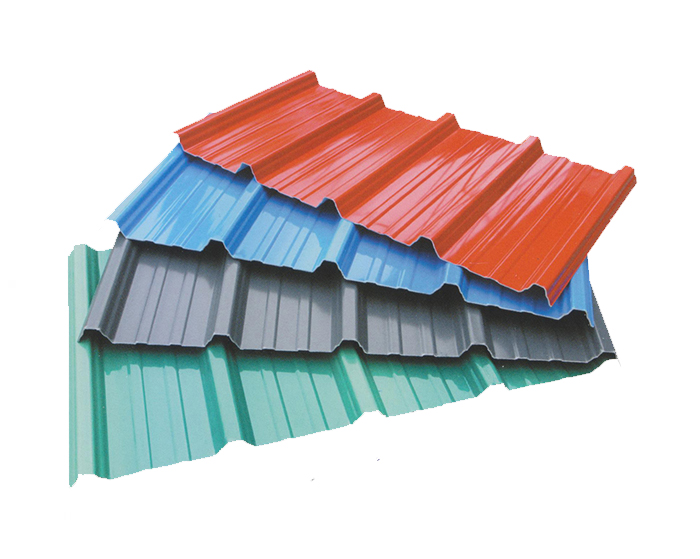

Corrugated Roofing Sheet Manufacturers in Pune

If you Are Looking For Corrugated Roofing Sheet Manufacturers in Pune So Stop Searching Durga Industries is here To Help You We have Qualified And Experience Expert And Main Thing Can not Compromise The Product Quality And Clients Satisfaction We at Durga Industries Manufacturing Corrugated roofing sheets have repetitive folds on their surface. The ridge and grooves make them stronger and durable. Corrugated roofing sheets are mostly used in agricultural building, garages, domestic sheds etc. They can withstand harsh weather condition. Depending on the pollution levels in the region where they are installed, they can last up to 5-10 years. These roofing sheets are coated with polyester paint or PVC plastisol. PVC plastisol coated corrugated sheets are durable and last up to 25-30 years.

Material Selection:

Corrugated roofing sheets can be made from various materials, including metal (such as steel or aluminum), plastic, or fiberglass. The choice of material depends on factors like cost, durability, and the intended use.

Sheet Forming:

If metal is the chosen material, large rolls or sheets of the base material are first unrolled or cut to the desired size.

Corrugation:

The key characteristic of corrugated roofing sheets is their corrugated or wavy profile. This profile adds strength and rigidity to the sheets. Corrugation is typically achieved by passing the flat sheets through a set of rollers with corrugated patterns.

Cutting:

After corrugation, the sheets are cut to the required length. This can be done using mechanical shears, saws, or other cutting equipment.

Coating (Optional):

Depending on the material and intended use, the roofing sheets may be coated with protective substances. For metal sheets, this can involve applying a rust-resistant coating or painting.

Curing (if applicable):

For some materials like certain plastics or fiberglass, a curing process may be necessary to harden and set the material. This often involves exposure to heat or UV radiation.

Quality Control:

Inspection of the corrugated sheets is crucial to ensure they meet quality standards. Common quality checks include checking for defects in the corrugation, size, and coating (if applicable).

Packaging:

Once the roofing sheets pass quality control, they are typically bundled or packaged for shipping and distribution. Proper packaging helps prevent damage during transit.

Shipping:

The finished corrugated roofing sheets are shipped to distributors, retailers, or construction sites for installation.

Installation:

Finally, on-site installation involves attaching the corrugated roofing sheets to the roof structure using fasteners such as screws or nails. Proper installation techniques are crucial to ensure the roof is weather-tight and secure.

It's worth noting that the exact manufacturing process can vary depending on the specific type of corrugated roofing material and the machinery used by the manufacturer. Additionally, safety precautions should be taken during manufacturing, especially when dealing with metal sheets and machinery, to protect workers and ensure product quality.