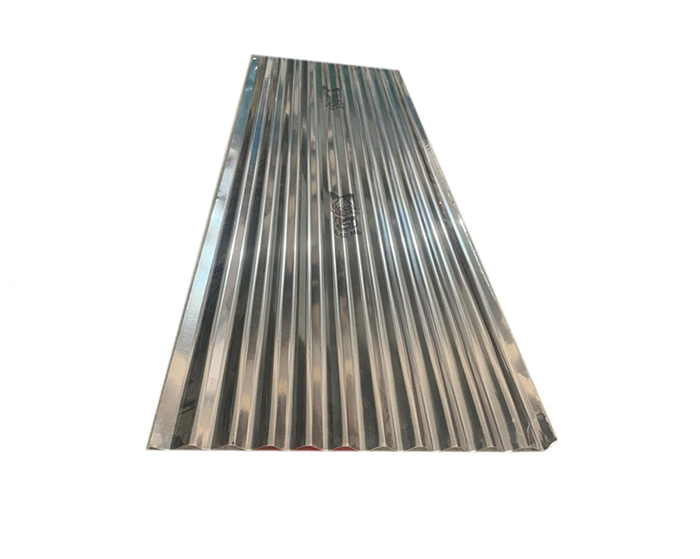

Galvinized Roofing Sheets Manufacturers in Pune

The manufacturing of galvanized steel sheets, often referred to as "GP sheets," involves a process called galvanization. Galvanization is the process of applying a protective zinc coating to steel or iron to prevent rusting and corrosion. This process provides excellent corrosion resistance and is commonly used in various applications, such as roofing, fencing, automotive parts, and construction materials. if you Are Looking For galvanized steel sheets So Stop Searching Durga Industries is here To Help You We have Qualified And Experience Expert And Main Thing Can not Compromise The Product Quality And Clients Satisfaction

Raw Material Selection:

The primary raw material is cold-rolled steel or hot-rolled steel coils. Cold-rolled steel is preferred for its smooth surface finish, which helps in achieving a uniform coating.

Cleaning and Surface Preparation:

The steel coils are cleaned thoroughly to remove any dirt, oil, or other contaminants. This is typically done through a process called pickling, where the steel is immersed in an acid solution to remove scale and rust. After pickling, the steel is rinsed with water.

Fluxing:

The cleaned steel is then immersed in a flux solution. Fluxing helps remove any remaining oxides on the steel surface and prepares it for the galvanizing process.

Galvanizing Bath:

The fluxed steel coils are dipped into a bath of molten zinc (typically at a temperature around 450-460°C or 850-870°F). The zinc bath is maintained at this temperature to keep the zinc in a liquid state.

Hot-Dip Galvanizing:

The steel coils are slowly passed through the molten zinc bath. As the steel enters the bath, it reacts with the zinc to form a series of zinc-iron alloy layers (the galvanized coating) on the steel's surface. The thickness of the coating can be controlled by the speed at which the steel is pulled out of the bath.

Cooling and Solidification:

After exiting the zinc bath, the galvanized steel is cooled rapidly, which solidifies the zinc coating. This process is often referred to as quenching.

Inspection:

The GP sheets are thoroughly inspected for uniformity of the zinc coating, adherence to quality standards, and any defects that may have occurred during the galvanizing process.

Cutting and Slitting:

The galvanized steel coils are then cut and slit into the desired sheet sizes and dimensions according to customer specifications.

Packaging and Shipping:

The GP sheets are packaged and prepared for shipment to customers or further processing facilities.

It's important to note that the quality of the GP sheets depends on various factors, including the quality of the steel used, the cleanliness of the surface, the thickness of the zinc coating, and the precision of the manufacturing process. Proper quality control and adherence to industry standards are essential to producing high-quality GP sheets with excellent corrosion resistance. Additionally, different variations of the galvanizing process may be used depending on the specific requirements of the application.