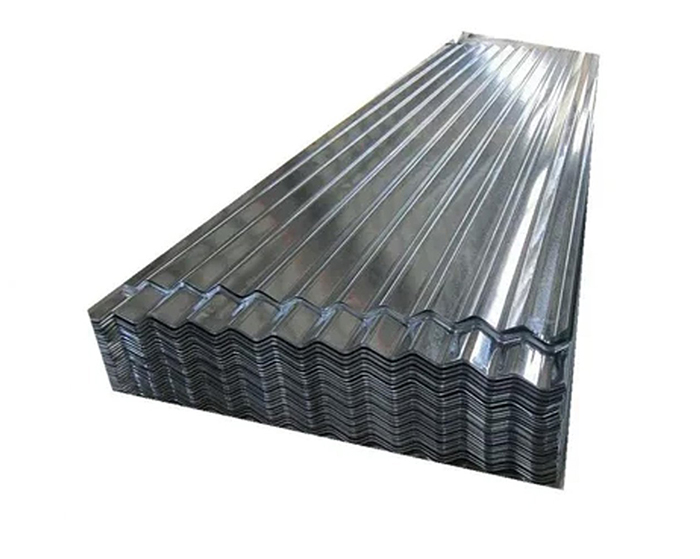

Mild Steel Roofing Sheets Manufacturers in Pune

if you Are Looking For Mild Steel Roofing Sheets Manufacturers in Pune So Stop Searching Durga Industries is here To Help You We have Qualified And Experience Expert And Main Thing Can not Compromise The Product Quality And Clients Satisfaction Manufacturing Mild Steel Roofing Sheets involves several steps in the process, from raw material preparation to the final product. if you Are Looking For Mild Steel Roofing Sheets Manufacturers in Pune So Stop Searching Durga Industries is here To Help You We have Qualified And Experience Expert And Main Thing Can not Compromise The Product Quality And Clients Satisfaction

Raw Material Preparation:

The primary raw material for mild steel roofing sheets is cold-rolled or hot-rolled mild steel coils. These coils are typically made of low carbon steel.

The steel coils are inspected for quality and defects before they are used in the manufacturing process.

Uncoiling and Leveling:

The steel coils are uncoiled and passed through a leveling machine to ensure a flat and even surface.

Cleaning and Pre-Treatment:

The surface of the steel sheets may be cleaned to remove any contaminants, rust, or oils.

A pre-treatment process, such as applying a phosphate coating, may be used to enhance the adhesion of subsequent coatings, like paint or zinc.

Roll Forming:

Roll forming is a critical step where the flat steel sheets are passed through a series of rollers and gradually shaped into the desired profile for roofing sheets.

These rollers can create various profiles like corrugated, trapezoidal, or standing seam, depending on the design requirements.

Cutting and Shearing:

After roll forming, the continuous sheet is cut into individual roofing sheet lengths using shearing machines.

The sheets are cut to the desired length, depending on the customer's specifications.

Coating (Optional):

Depending on the intended use and customer preferences, the mild steel roofing sheets may be coated with various materials for corrosion resistance and aesthetics.

Common coatings include paint or zinc (galvanized).

Quality Control:

Throughout the manufacturing process, quality control measures are implemented to check for defects, accurate dimensions, and proper coating application.

Any substandard sheets are rejected.

Packaging and Shipping:

The finished roofing sheets are stacked, bundled, and packaged for transportation to distribution centers or customers.

Proper packaging helps prevent damage during shipping and storage.

Installation:

Once the roofing sheets reach the customer or construction site, they are installed using appropriate fasteners and roofing accessories.

It's important to note that the specific manufacturing process can vary depending on the type of roofing sheet, its thickness, coating requirements, and other factors. Additionally, safety precautions and environmental considerations should be taken into account during the manufacturing process, as steel production can involve potentially hazardous materials and emissions.

Local regulations, industry standards, and quality control procedures must also be adhered to throughout the manufacturing process to ensure the production of high-quality mild steel roofing sheets.